Features

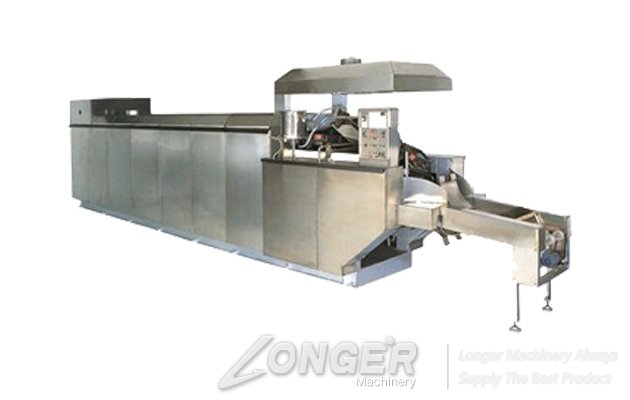

It is controlled by a PLC made by SIEMENS brand. The functions of the baking oven are fully automatic from spreading batter on the plates to the procedure of baked wafer sheets coming out of the oven. Baking is even and produces good quality wafer sheets for next procedure. In PLC there is a PID controller which is used to control the temperature of the baking plates automatically .The collection of required signal of PID is supplied by infrared sensor which is produced by RAYTEK of U.S.A .The oven status display and the data reset are supplied by SIEMENS by Japan. Contactor switch is supplied by SCHENEIDER Company in China. The stepping wheel bearings of the mould rack are SKF Explorer made in France. The pressing roller bearings are SKF Explorer made in Austria. The pneumatic components are supplied by FESTO/SMC. The main drive will be SEW Eurodrive of German brand. There is an automatic spurring-cleaned device at the bottom of the baking oven. There is second pressure relief valve from Madas.

Advantages

Advantages

1. In according to the clients ' requirements ,we can make a wide range of size and shape cream (chocolate ) filled wafer biscuit full automatically.

As the most important equipment of full-automatic wafer production line, tunnel electric baking machine has extraordinarily outstanding performances.

2. The whole shell of the production line adopts 304 Stainless Steel in accordance with the health and safety standard.

3. Unanimous heat colors of wafer block. Thanks to the scientific selection of heating components, superior material selection for baking plate and reasonable die carrier structure, the heat colors of the center and periphery of the wafer block having been baked are unanimous.

Technical Data

| Model | LGDL-63-1 |

| Heat Source | Electric |

| Moulds Quantity | 63 pairs |

| Moulds Type | Cast Iron Electric Plates |

| Plates Size | 470*325*25mm |

| Size of Wafer Stripe | 3.0*3.0*0.5 |

| Wafer Size | 2.0-3.0mm |

| Baking Time | 90~120 seconds(the thickness of wafer<3mm, temperature is 180℃) |

| Capacity | 2520pieces/h(the thickness of wafer:2.3mm) |

| SUS 304 Material Parts | Oven door, hood, pulp barrels, shell |

| SUS 304 Material Thickness | 1.0mm(±0.05mm) |

| Food Contacting Parts Material | SUS 304 or Cast Iron |

| Touch Screen | 10 inches, E-view |

| Mould Base | Cast Iron |

| Oven Frame | High Quality Carbon Steel, Silver paint spraying antirust |

| Walking Wheel Bearing | HRB |

| Door Insulation Materials | Aluminum silicate, rock wool |

| Slurry System | Frequency conversion slurry system |

| Slurry Motor | 0.75kw, SEW |

| Leaching pulp, the host drive inverter | Tai Da Brand |

| Circuit breaker, ac contactor, button | Chint, Shuangke |

| Main Motor | 1.5kw, Jin Fuling |

| Motor Reducer | Xidi transmission |

| Max operating current | 420A/350V AC |

| Max power consumption | About 230KW |

| Electric | 380V, 50Hz, 3 phases |

| Dimension | 12380*1560*2320mm |

| Weight | 11500KG |

You are here:

You are here: