Features

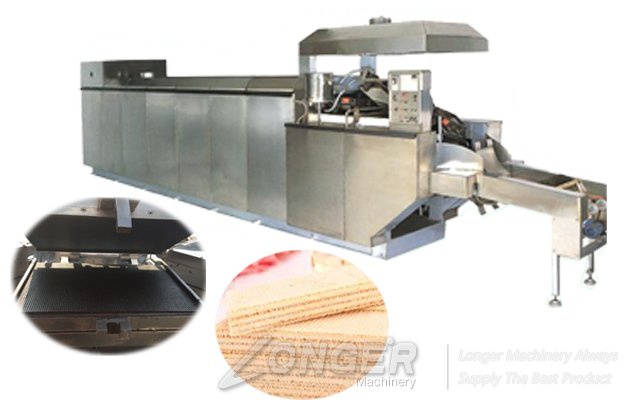

This wafer biscuit production line need at least ten machines:Electric electric heating oven(most important part; splicing machine; wafer sheet cooling machine(runs slowly to cool down and convey the wafer block; cream spreading machine; wafer cutting machine(the size can be customized by customers’ requirements); blender machine;cream mixer; swashing machine; sugar grinder; air compressor etc. If customers have some machines before, we can match others to meet their requirements, for example: wafer biscuit packing machine. The cutting size can be customized by customers’ requirements. Also, we can change the voltage for customers.

Advantages

High rate of certified products with finished product rate of not less than 98%. Because of uniform heating and unanimous heat colors, the demoulding rate of biscuit is high with improving rate of certified products accordingly.

About the wafer sheet cooling machine:Materials: The machine frame is made of steel with international standard and the cover adopts imported 304 stainless steel plate with thickness of 1.2mm and Φ6 stainless raw material. The machine runs slowly to cool down and convey the wafer block

About the wafer sheet cooling machine:Materials: The machine frame is made of steel with international standard and the cover adopts imported 304 stainless steel plate with thickness of 1.2mm and Φ6 stainless raw material. The machine runs slowly to cool down and convey the wafer block

Technical Data

| Model | LGDL-15-1 |

| Moulds quantity | 15 |

| Moulds size | 470*325*25mm |

| Size of wafer stripe | 3.0*3.0*0.5 |

| Wafer thickness | 2.0-3.0mm |

| Baking time | 95~120 seconds(the thickness of wafer<2.5mm) |

| Capacity | 560 pieces/h(the thickness of wafer:2.3mm) |

| Component materials in contact with food | 304 # stainless steel or cast iron |

| Average Power | 1.5kw |

| Voltage | 3-phase,380V,50 Hz |

| Gas consumption | About 40m3/h |

| Dimension | 3260*1560*2320mm |

| Weight | 5700kg |

You are here:

You are here: