Features

LG Series Biscuit Production line is the primary choice for the production of kinds of hard and soft biscuit. The biscuit plant equipment can be combined and displayed according to customer’s local space or biscuit technical requirement.Adopting hearing-medium conduction technology with heating oil as medium,the plant is a new generation product developed

exclusively in China based on the advanced structure of existing plants from domestic market and abroad.If offers an ideal solution for lower power consumption and overall production cost,and keeping the same surface color for all biscuits.The plant mainly consists of mixing system,automatic feeding system, tunnel-type oven, sheet feeding and cooling device,coating machine,cutter and organic heating medium boiler, etc. With compact structure and unique reliability, the plant is one of the most preferred equipment in foodstuff industry.

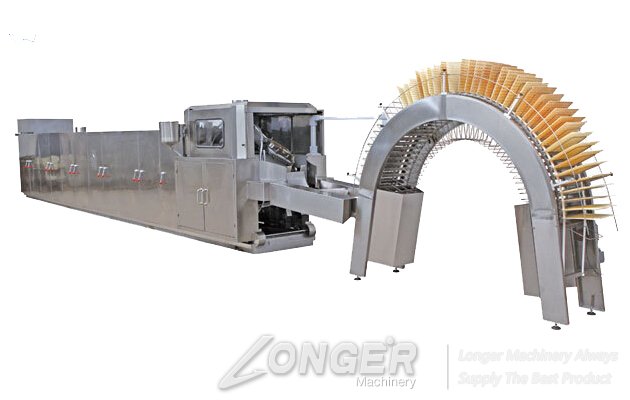

The machines frame of Best Seller Automatic Gas Type Wafer Production line is made of steel with international standard and the cover adopts imported 304 stainless steel plate with1.2mm thickness.

Advantages

1.By changing the moulds and recipes, this plant is able to produce various types of high quality biscuit, such as cream biscuit, sandwiching biscuit, soda cracker biscuit, animal biscuit, vegetable biscuit etc.

2.Kinds of moulds are available. You can buy different kinds of moulds from our company. We offer one package service.

3.There are diversified heating source for your operation (Electric, gas, fuel oil).

4.We can design kinds of roll forming machines according to your specific profile drawing.

5.We have approved by CE、ISO and SGS. They all are proves of our high quality.

6.The workmanship is very good, so it will save you much trouble to mend it

Technical Data

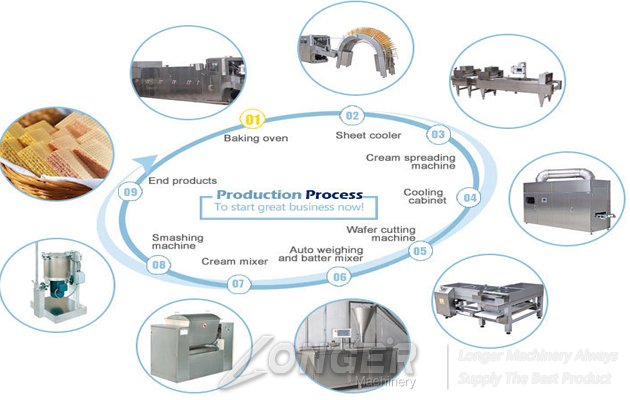

| Equipment Name | Dimension(mm) | Power(kw) |

| Batter Mixer | 1720*1200*930 | 4.5 |

| Gas Baking Oven(GGHG-27) | 6740*1600*2260 | 5.52 |

| Wafer sheet connecting machine | 1050*700*940 | 0.18 |

| Vertical-type wafer sheet cooler LPL | 3250*700*2780 | 0.37 |

| Sheet Collecting Machine | 2000*700*825 | 0.18 |

| Cream spreading machine | 3000*1160*1300 |

380V-2.24 220V-2 |

| Vertical cooling tower | 3140*1160*2700 | 1.21 |

| Cold Blower | 2200*1100*1800 | 10.75 |

| Laminator/Transportation system | 1115*700*870 | 0.18 |

| Mechical Blade-type Cutting Machine | 2000*1700*880 | 0.75 |

| Distributing machine | ||

| Separating conveyor | 1840*850*1350 | 0.18 |

| Cream Mixer(with water jacket) | 1830*700*1240 | 5.05 |

| Smashing machine | 670*660*1200 | 3 |

You are here:

You are here: