Features

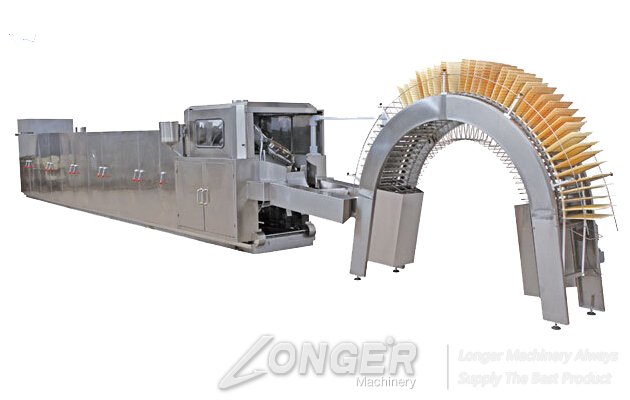

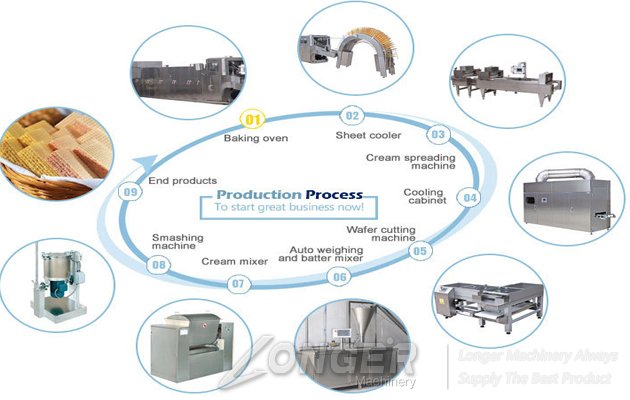

LG Series Wafer Production line is the primary choice for the production of kinds of hard and soft biscuit. The biscuit plant equipment can be combined and displayed according to customer’s local space or biscuit technical requirement. Adopting hearing-medium conduction technology with heating oil as medium, the plant is a new generation product developed exclusively in China based on the advanced structure of existing plants from domestic market and abroad. If offers an ideal solution for lower power consumption and overall production cost, and keeping the same surface color for all biscuits. The plant mainly consists of mixing system,automatic feeding system, tunnel-type oven, sheet feeding and cooling device, coating machine,cutter and organic heating medium boiler, etc. With compact structure and unique reliability, the plant is one of the most preferred equipment in foodstuff industry.

According to 1:1 proportion of pie slices and cream, the capacity is 86kg/h(the more cream, the bigger capacity).

According to 1:1 proportion of pie slices and cream, the capacity is 86kg/h(the more cream, the bigger capacity).

Technical Data

| Name | Quantity | |

| 1 | 27 moulds flat automatic gas oven | 1 |

| 2 | splicing machine | 1 |

| 3 | Wafer sheet screening machine | 1 |

| 4 | Vertical cooling machine | 1 |

| 5 | Cream spreading machine | 1 |

| 6 | Wafer cutting machine | 1 |

| 7 | Blender Machine | 1 |

| 8 | cream mixer | 1 |

| 9 | Swashing Machine | 1 |

| 10 | Sugar grinder | 1 |

| 11 | air compressor | 1 |

| 12 | Packing machine | 1 |

| Model | LGDL-27-1 |

| heat source | natural gas or liquefied gas |

| moulds quantity | 27 |

| moulds size | 470*325*35mm |

| size of wafer stripe | 3.0*3.0*0.5 |

| wafer size | 2.3-2.8mm |

| baking time |

95~120 seconds wafer thickness<2.5mm |

| capacity |

1330pieces/h wafer thickness:2.3mm |

| Component materials in contact with food | 304stainless steel or cast iron |

| Average Power | 1.5kw |

| voltage | 3-phase,380V,50 Hz |

| gas consumption | About 21m3/h |

| Dimension | 5540*1560*2320mm |

| weight | 7700kg |

You are here:

You are here: